|

|

|

|

|

The straight edge here shows how badly the "crown" of the board has reversed

Compare with the photo below that shows a proper crown.

It is funny, people say "there are no cracks in the sound board, I guess we can keep it" Cracks are not the problem, crown is. |

|

This is the new sound board for the piano. The photo shows a proper crown. |

|

Ribs have been made and fitted. |

|

Here the ribs are being shaped. If you enlarge the photo you can see the ribs to the right have not been shaped yet. |

|

The afternoon sun provides pleanty of light to see detail.

|

|

After the old cap is removed, all old bridge pin holes are plugged with maple pegs and glue.

There are approx. 472 bridge pin holes

Here is evidence that the piano has been rebuilt before. There are many such places.

Unfortunatly, the poor sound of the piano is attributed to previously incomplete work.

|

|

The new cap wood is glued on in the same arc as the bridge will be when it is installed on the sound board. This reduces unnecessary stress. |

|

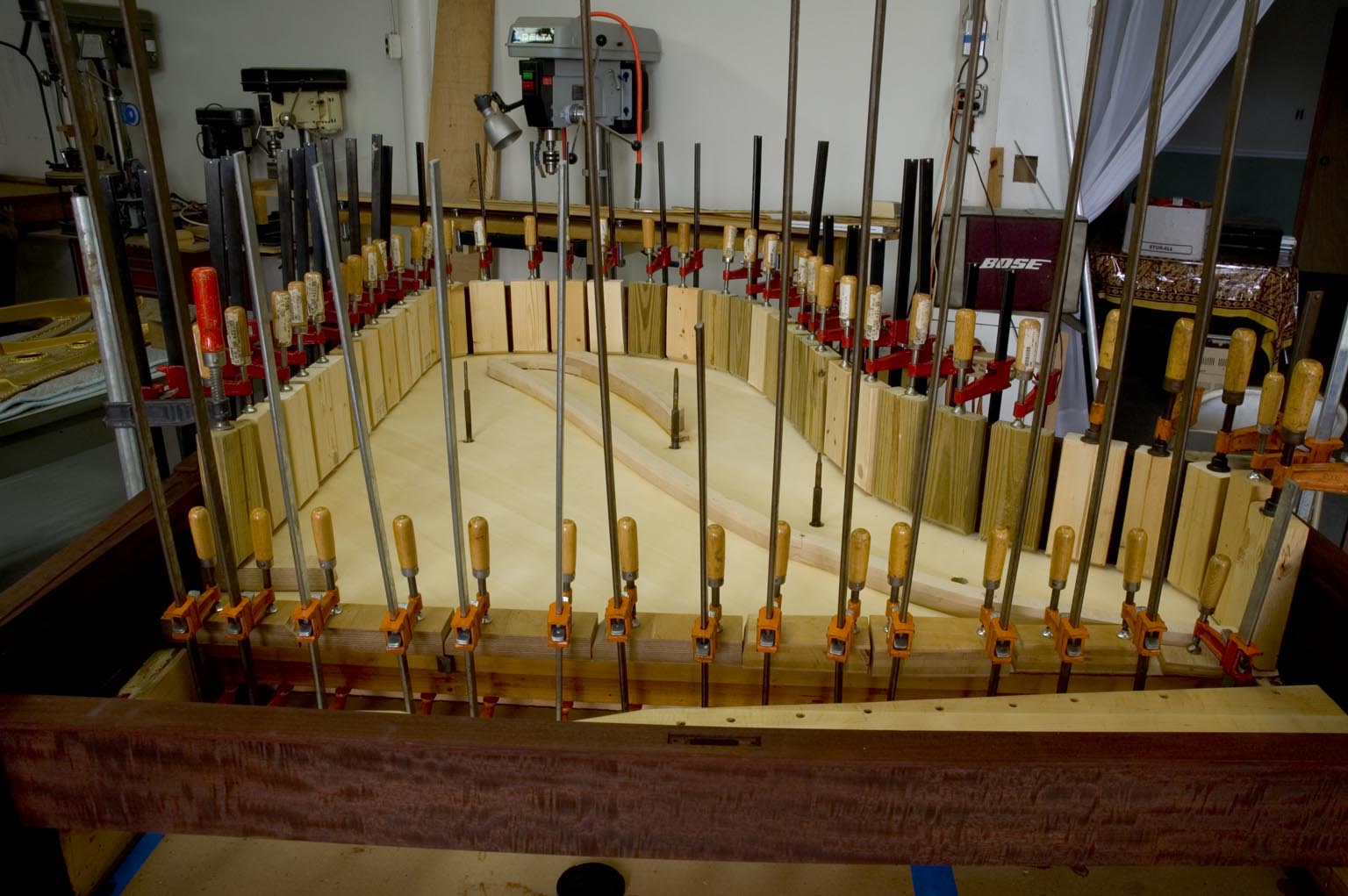

This press was built specifically to glue the bridges to the sound board. You can see the arc from left to right.

The press also arcs front to back. The bridge is now glued to the board with all angles matching that of the crown of the board.The sound board is being glued into the piano case

. |

|

The Sound Board is glued into the piano. |